process intensification

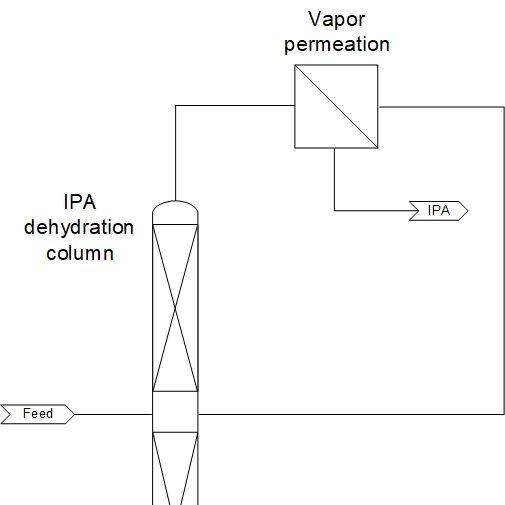

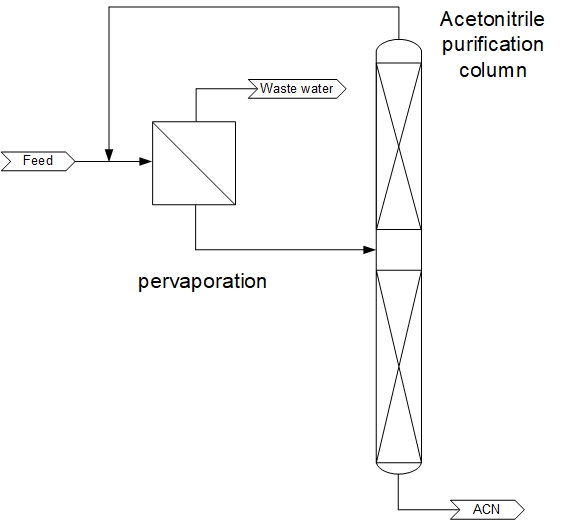

m-PS offers hybrid separation process concepts for your production plant by applying process intensification strategies. Smart combination of different technologies and/or unit operations enables efficient processes with regards to energy consumption, equipment costs and foot print.

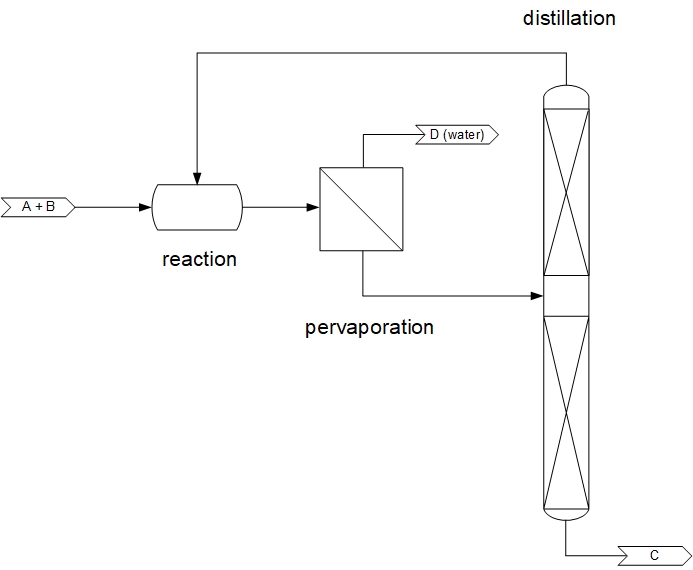

For example the combination of reaction and simultaneous separation of one or more reaction products significantly increases the reaction conversion of equilibrium limited condensation reactions. Often reaction is combined with distillation in one unit operation, so called reactive distillation: The distillation column has a reaction zone in which the reaction takes place. The products are simultaneously removed from this zone increasing the reaction conversion. An alternative to this concept is distillation with side reactors: Liquid side draws are pumped through fixed bed reactors which are placed aside the distillation column. The reactor outlet flows back to the distillation column.

Another possible separation method is pervaporation which allows the removal of water from the reaction mixture with hydrophilic membranes: The feed is pumped through a combination of fixed bed reactor and a pervaporation membrane module in batch or feed-and bleed operation mode.

Many times the optimum is a combination of two or more technologies to complete a specific reaction and separation task.

With experience in reaction and thermal separation technologies we can carry out process intensification studies to debottleneck your existing production process or to propose an optimized new process concept. Often laboratory test work is needed to properly validate the design and to allow a safe scale-up of hybrid systems. m-PS can support you in carrying out the required steps for commercial implementation.